Milling allows for precise cutting of any shapes from various materials, ensuring a smooth, matte edge surface. For clear plexiglass, diamond milling can be used to give the edges a mirror-like transparency effect. Milling is an excellent choice for projects requiring high precision and aesthetic finish.

Laser technology enables fast and precise cutting of shapes from many types of materials. The laser cutting process melts the edges, resulting in a transparent and glossy effect. Although the edge surface is not perfectly flat, slight irregularities add a distinctive visual effect.

Plotter cutting is mainly used for materials such as self-adhesive films or thin cardboard. It allows for precise cutting of both simple and complex shapes in a short time. This method is ideal for projects requiring high repeatability and low production costs.

Traditional guillotine cutting provides a simple and economical processing method. Small marks and indentations may remain on the cutting edges, which can be easily removed using sandpaper. The option to smooth the edges allows for an aesthetic finish.

Summary:

Each cutting technology has its unique features that can be tailored to the specifics of the project. With wide technological capabilities, we can ensure precise and aesthetic processing of any material, meeting even the most demanding customer expectations.

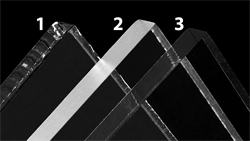

1. Cutting - CO2 laser

2. Plexi milling

3. Edge polishing with a diamond cutter

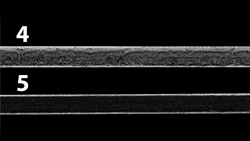

4. TuBond cutting with a guillotine

5. Tu-bond milling

The Kimla 1326 industrial gantry plotter is a modern device for precise processing of various materials using milling, knife cutting, and creasing methods.

Elements cut on the milling machine have sharp edges and remnants of the top layer of the material. Edge rounding and removal of remnants are the responsibility of the Customer - we recommend using sandpaper with a grit of 150-200.

The Kimla 1326 milling machine provides precise and versatile processing of various materials, making it an ideal solution for the advertising, industrial, and packaging production industries.

The process of edge polishing with a monocrystalline diamond blade on the Kimla machine applies to clear plexiglass and involves using a special diamond tool to achieve smooth, transparent edges after milling.

Diamond polishing is an effective method, especially for high-quality plexiglass elements used in advertising and displays, where perfect finish and detail aesthetics are important.

Bending composite materials, such as Tu-Bond (DiBond), is performed by cutting a V-groove using a conical cutter. This process allows for precise bending of the panel without damaging the outer aluminum layers, ensuring an aesthetic and durable finish.

We also use Tu-Bond edge bending in the plaque and sign calculator. This is to stiffen the front surface and transform the flat panel into a spatial structure. This process increases the durability of the plaque and improves its aesthetics, eliminating the need for additional frames or reinforcements.

Thanks to the use of a conical cutter, the Kimla milling machine allows for precise and repeatable bending of Tu-Bond (DiBond), making it an ideal solution for the advertising, construction, and industrial sectors.

Creasing/folding is a process that allows for aesthetic and precise folding of printed materials.

For creasing, perforating, or folding non-standard projects (not defined in templates), you should:

Perforation is a bookbinding process that involves making a series of small cuts along a line, allowing easy tearing of parts of a paper sheet. This solution allows for convenient separation of material fragments, such as coupons, forms, or tickets, without using scissors or cutting tools.

Saddle stitching is a bookbinding method where paper sheets are folded and stapled with metal staples along the spine. This way of connecting pages is durable and aesthetic, and also allows easy opening of the brochure. Saddle stitching is ideal for thin brochures, guides, notebooks, and booklets.