| Product Information |

| Opis produktu: |

In our plate range, over 80 different materials in 13 groups are available (see specification) with the following options to choose from::

|

| Limitations | The maximum and minimum plate sizes are limited by:

- Size of available materials

- Machine working area

- Possibility of holding the material during processing

See the table below for specific limitations.| Technology/material | Maximum size [mm] | Minimum size [mm]* | | UV CMYK + White print | 710 x 510 | | | YAG laser engraving | ɸ 280 | | | CO2 laser engraving | 600 x 450 | | | Cutting – CO2 laser | 600 x 450 | 10 x 10 | | Diamond cutter edge polishing | 2550 x 1250 | 150 x 100 | | Custom shape milling | 2550 x 1250 | 150 x 100 | | Guillotine straight line trimming | 300 x 300 | 20 x 10 | | Plotter cutting | 1790 x 1190 | 20 x 10 | | Tu-Bond edge folding | 2550 x 1250 | 150 x 100 | | Edge polishing after guillotine cutting | 300 x 300 | 50 x 50 | | Hole drilling | ɸ 3 | | | Engraving laminates | 610 x 305 | | | Aluminium – all types | 508 x 304 | |

* For jobs consisting of two or more items, applies to the size of a single item.

|

| Available technologies | Marking and cutting technologies available for materials offered in our range:| Material | Available technology | | Laminates | Films | Aluminium | Steel | HIPS | Plexi | PCV | Tu-Bond | | UV CMYK + White print | x | | | | x | x | x | x | | CO2 laser engraving | x | x | x | | | x | | | | YAG laser engraving | | | x | x | | x1 | | x | | Cutting – CO2 laser | x | x | | | | x | x | | | Guillotine straight line trimming | | | x | x | x | | | x | | Plotter cutting | | | | | x2 | | | | | Curved-line milling | | | | | | x | x | x | | Diamond edge polishing | | | | | | x | | | | Edge polishing after guillotine cutting | | | | | | | | x | | Tu-Bond edge folding | | | | | | | | x | | Hole drilling | | | x | x | | | x | x |

1. Black plexiglass only.

2. Applies to up to 1 mm thickness only.

|

| Trimming | Available cutting technologies:

- Guillotine cutting leaves traces of knife pressure or slight tears, which you can easily smooth yourself using sandpaper, or you can order polishing of edges after cutting.

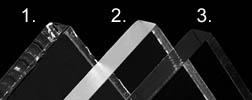

- Custom shape milling results in perfectly smooth cutting edges with matte surface. Additional polishing of edges with a diamond cutter used for transparent plexiglass results in a mirror-like effect, with a completely transparent surface with only barely visible cutter trace marks.

- Laser cutting results in a transparent, mirror-like surface, which, however, is not perfectly smooth as it is with the diamond cutter; slight irregularities after material melting may be visible.

1. Cutting – CO2 laser

2. Plexiglass milling

3. Diamond cutter edge polishing

4. Tu-Bond guillotine cutting

5. Tu-Bond milling

|

| Tu-Bond edge folding |

Thanks to the folding of the TuBond edge, the cutting edge is not visible, creating an impression of a thick, homogeneous aluminium plate with the edge in the colour of the plate front. The folded edge can also be printed over or engraved. The design template is generated individually for every size available in the price quote form. |

| Additional Information | Do not use solvents or pure alcohol to clean plexiglass. Using water with washing-up liquid or a 10% spirit or methylated spirit solution is recommended. |